Mixing test glazes

It’s important to wear a NIOSH certified mask whenever using dry glaze materials.

I guess mixing up glazes isn’t that big of a deal, but I’m sharing my technique just in case there are some absolute beginners out there.

I find it easier to use a digital scale, see my article here.

Glazes “don’t travel well”, in other words materials, application, and firings vary from studio to studio. Even for well-known glazes, it’s important to first make a small tests. For these tests, I use 50g or 100g of material and apply the test glaze to a number of different clay bodies.

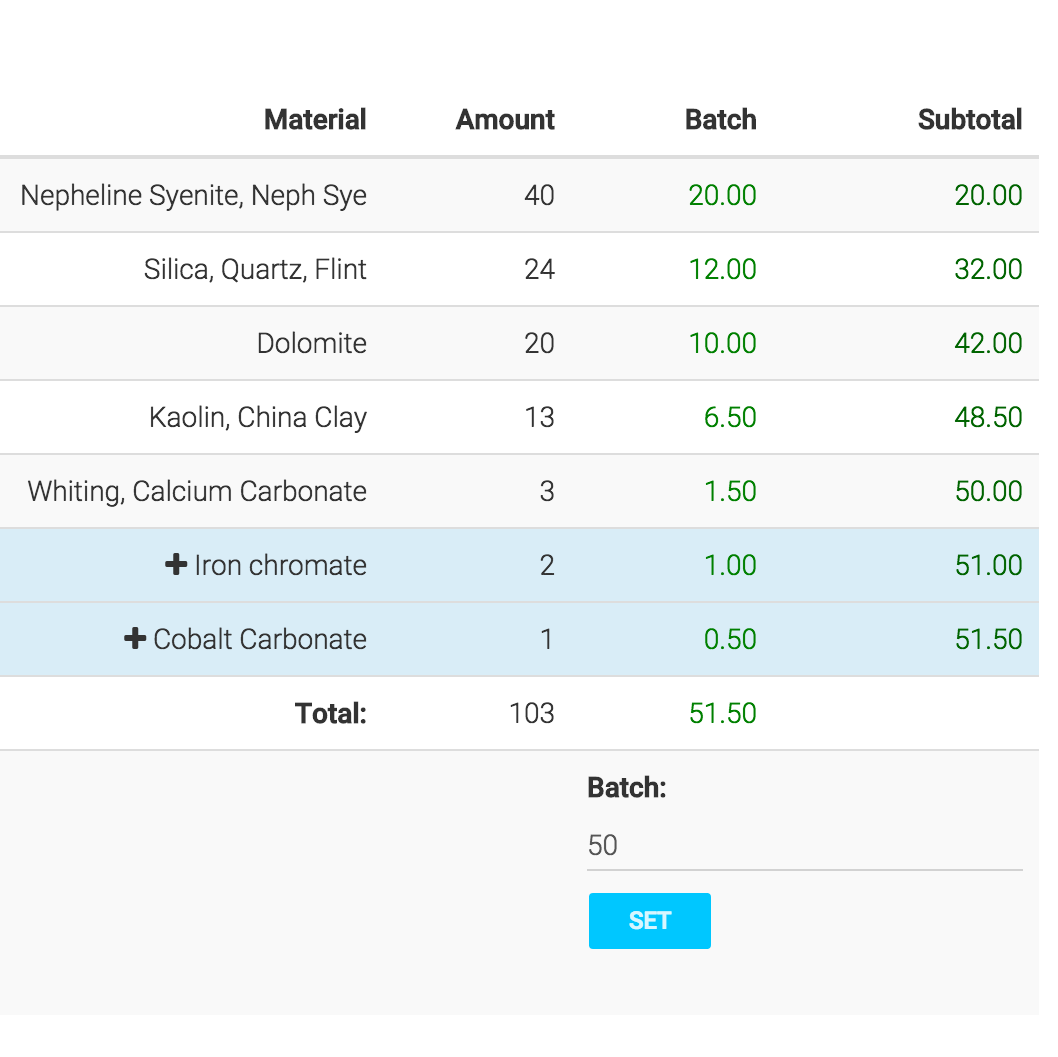

I use the Glazy Batch Calculator on my phone which will show you the subtotals for arbitrary amounts of total glaze materials.

Once I’m happy with a test, I mix up a larger batch of 1-2Kg. 1Kg is enough material to glaze small cups, 2Kg is a good amount for small bowls. These larger tests should reveal any problems with glaze suspension (is bentonite required?), application (cracking, peeling, etc.), and fired glaze defects. Once you have some nice results with 1Kg, you can finally move on to a big bucket of 5-10Kg.

Mixing up a test

I use cheap, reusable restaurant soup containers with lids. The size fits my small sieves perfectly, and they are easier to use than plastic cups. Glaze name & recipe is written on container with permanent marker.

Carefully measure out each ingredient into the bowl, placing into separate piles so that any extra material can be easily removed.

Dry mix the ingredients with a spoon until well dispersed.

For 100 grams of material, add about 50ml of water (less if your glaze has little or no clay). I am paranoid and use water from my reverse osmosis filter, as my tap water is hard and sometimes of questionable quality.

Wait a few minutes until the water has thoroughly soaked the materials, then stir. Glaze should be fairly thick, do not add too much water as you will be adding more as you go along.

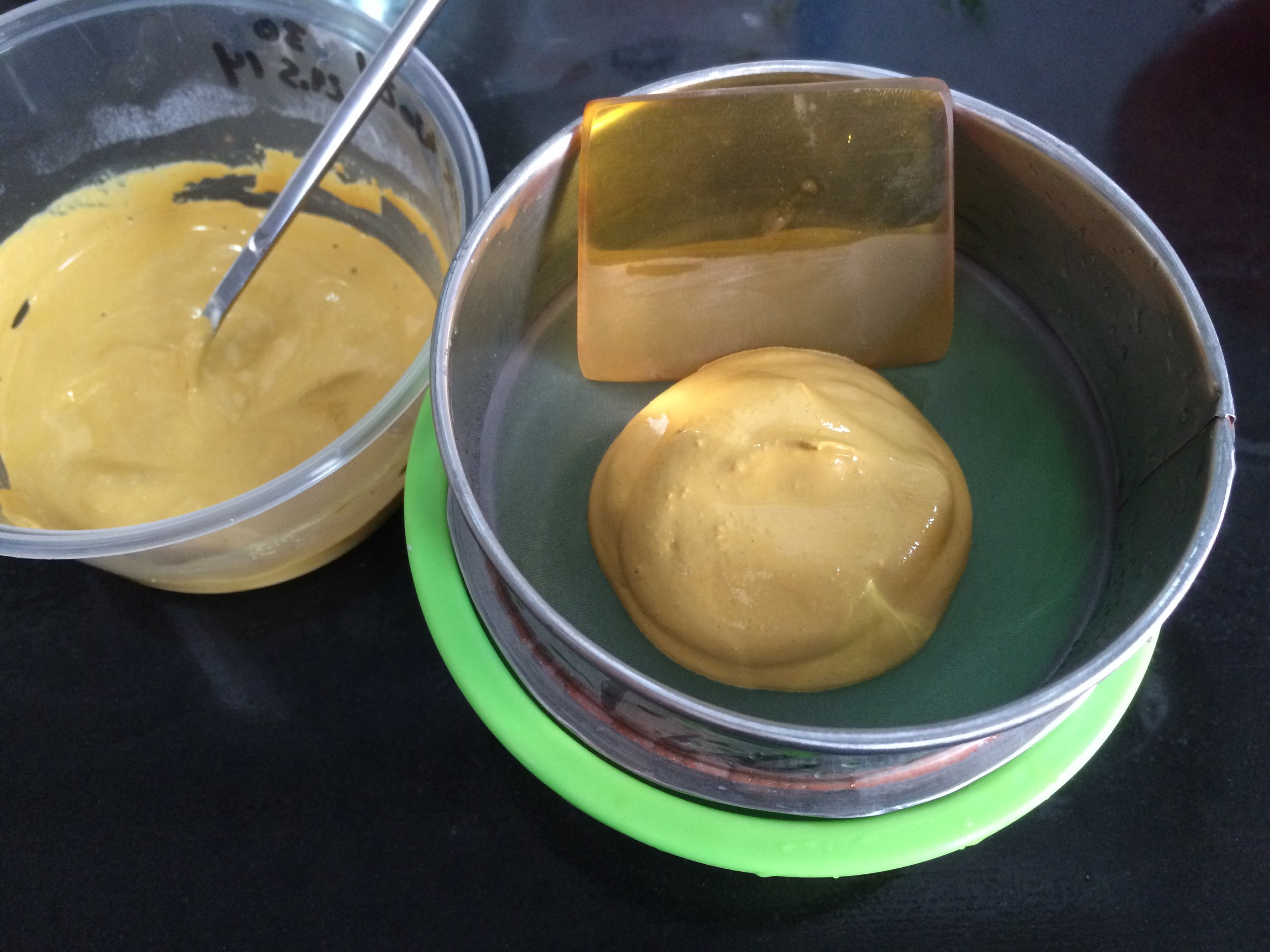

I use a stiff rib to scrape the glaze through the sieve. Do yourself a favor and get containers that perfectly fit your sieves.

The first pass takes the most work as the clays are broken apart.

Try not to lose any material, especially if preparing for volumetric blending. Use a water sprayer to clean the container, spoon, and sieve after each pass. But don't add too much water.

I do two or three passes through the sieve. After the final pass, the glaze should be creamy without any large grains or lumps.

Now you can slowly mix in a bit of water. I keep the glaze thicker than normal. Flat test tiles require the least amount of glaze.

Flat test tiles require the least amount of glaze for application. Here’s my article about how I make test tiles.

Sieve Mesh Size

For “natural” glazes containing large-grained materials or ashes, or in cases where homogeneity is not a concern, it’s fine to use a larger screen of 60-80 mesh. But in all other cases I use 120 mesh or smaller. Small mesh size is very important for glazes that contain small amounts of very important materials such as coloring oxides (e.g. cobalt and iron). But it’s also important to ensure that materials are adequately broken up and mixed (such as clays).

Below you can see two tests of the same batch of glaze fired in the same kiln. The glaze on the left was applied after passing the materials three times through an 80 mesh screen. The glaze on the right is the result of passing that same glaze once more through a 120 mesh screen.

A test celadon glaze. 100g of material passed through an 80 mesh screen 3 times. Note the iron spots.

Passing the exact same batch of glaze one more time through a 120 mesh screen adequately disperses the glaze materials.

Poorly dispersed colorants like iron are easy to see in fired glazes. But keep in mind that other “invisible” glaze ingredients like clays, feldspar, etc. also need to be well-dispersed and mixed in order to ensure the glaze melts properly. If you use a 60-mesh screen for tests and then a 120-mesh screen for large glaze batches, there will be differences between the fired results.